| 中文 | ENGLISH |

| HOME | ABOUT US | INSPECTION | FACTORY AUDIT | CONTACT US | MEDIA NEWS |

|

| --OUR SERVICES-- | ||||||

|

Initial Production Check (IPC) | |||||

| --Production completed: 5%--10% |

||||||

| Initial or first piece inspections can be conducted to check semi-finished products, raw materials, accessories, and production lines, in order to confirm whether suppliers understand and have a good grasp of product production requirements and detail handling. This helps to detect problems as early as possible, avoid batch defective products, and thus form product production risks, correct errors in a timely manner, improve production processes, increase production efficiency, ensure stable quality of bulk goods, and complete production tasks on time and with quality. Prevent various unreasonable and wasteful practices, as well as potential defects that may arise from them. To meet your requirements and quality objectives. | ||||||

|

During Production Check (DUPRO) | |||||

| --Production completed: 30%--50% | ||||||

| With the mass production of bulk goods, various technical indicators and worker proficiency tend to stabilize, and the product quality also tends to stabilize. Any quality problems that may occur can be basically discovered. At this time, conducting random inspections can help you timely understand whether the products produced by the factory are consistent with the confirmed samples or requirements, and whether there are any changes in raw materials or specifications? Has there been any significant fluctuation in product quality due to the relocation of production workers, changes in production lines, or other factors. To ensure that the production schedule and delivery time are not affected and to reduce the credit risk of delayed delivery. | ||||||

|

Final Random Inspection(FRI) | |||||

| --Production completed: 100% Packaging completed: 80% | ||||||

The most effective inspection method for confirming the quality level of the entire batch of goods is when the product is 100% completed and at least 80% packaged. The sampling plan refers to the standard ISO2859/ANSI/ASOZ1.4/BS6001 for AQL sampling, and also refers to the customized product inspection specifications and special requirements for inspection. A detailed inspection report is generated based on the defined AQL. |

||||||

|

Container Loading Supervision(CLS) | |||||

| -- Applicable after the goods have passed the acceptance inspection | ||||||

Monitor the entire container loading process at the factory, warehouse, dock, or your designated location. The inspector checks the quality and quantity of the goods to be shipped based on the order or packing list provided by the customer. While ensuring that the container is in good condition, the inspector ensures that the loading quantity, style, and requirements of the container are consistent, the loading method is correct, the product safety is ensured, and the quantity is accurately delivered to the destination. Even for qualified products, improper or non-standard loading methods may lead to quality issues, or due to poor container loading, various problems such as packaging or product moisture may occur. |

||||||

|

Sample Picking Service(SPS) | |||||

| -- Ensure the objectivity and representativeness of the samples | ||||||

| Professional on-site operation procedures ensure that your samples arrive accurately and promptly at your designated destination. | ||||||

| Core Values | Core Mission | Company Vision | ||||

| Integrity Rigor Professionalism Efficiency Gratitude | To serve our customers with scientific methods, fair attitudes, standardized testing, and accurate testing data, and to build a solid quality control defense line. | Becoming a third-party quality service provider with global influence | ||||

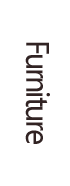

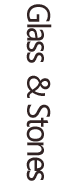

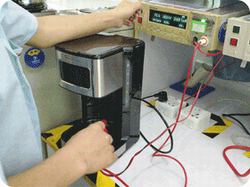

| --INSPECTION CASE-- | ||||||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

| Our Services | Resource Centre | About Us | Customer Service | Follow Us | |||

| Consumer Goods Inspection | Guidelines for Traders | Company Profile | E-MAIL:info@eqci.com.cn |  |

|||

| Industrial Product Inspection | News Center | Talent Recruitment | Business Consulting:18100259835 | ||||

| Supplier Audit | Inspection Report | Coverage Area | Complaint Call:0757-28108051 | ||||

| VR panoramic factory inspection | AQL | Voice Of The Customer | Scan the QR code on WhatsApp and follow now |

||||

| CopyRight© 2004 ---------------· EQCI--------------- |